Dimensions

CCL Masonry Stop Socks are supplied in 1200mm lengths and are factory cut to suit cavity widths from 50mm to 150mm.

Cavities wider than 150mm can be accommodated, although CCL Firestop Slab may be a more suitable application.

Standards and Performance

The mineral wool core of a CCL Masonry Stop Sock achieves a fire classification of Euroclass A1 as defined in BS EN 13501-1.

The correct use of a CCL Masonry Stop Sock will exceed the requirement for a 30 minute cavity fire barrier as defined in Approved Document B of the Building Regulations 2010 (2019 edition). Table B3 of Appendix B. Detailed performance information can be found on data sheet 1018

The product has been independently tested adopting procedures and criteria from BS476 & BS EN 1366. Approved Document B of the Building Regulations 2010 (2019 edition), Section 8 details the requirement and purpose for which a cavity barrier should be installed.

CCL Masonry Stop Socks comply with the robust details accepted to provide a solution which satisfies the Approved Document E 2003 (2015 edition) of the Building Regulations relating to the transmission of sound.

Fixing

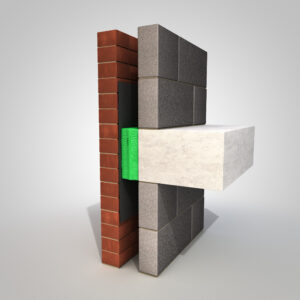

CCL Masonry Stop Socks are supplied 10mm to 15mm thicker than the cavity in which they are to be installed and are friction fitted during the brickwork process.

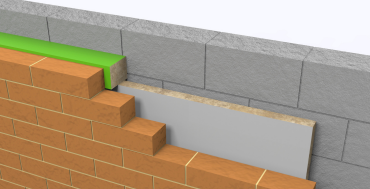

During vertical installation it is advisable to place a length of damp proof course between the cavity stop sock and the outer leaf.

During horizontal installation it is advisable to protect the Masonry Stop Sock with a damp proof course or cavity tray immediately above with a minimum 100mm upstand.

Special attention must be paid to the joints to ensure these are very closely butted.

Cavity barriers may fail at the joints if a gap is left.

The Cavity Barrier should fully fill the whole cavity as shown in Diagram (B) below.