Description

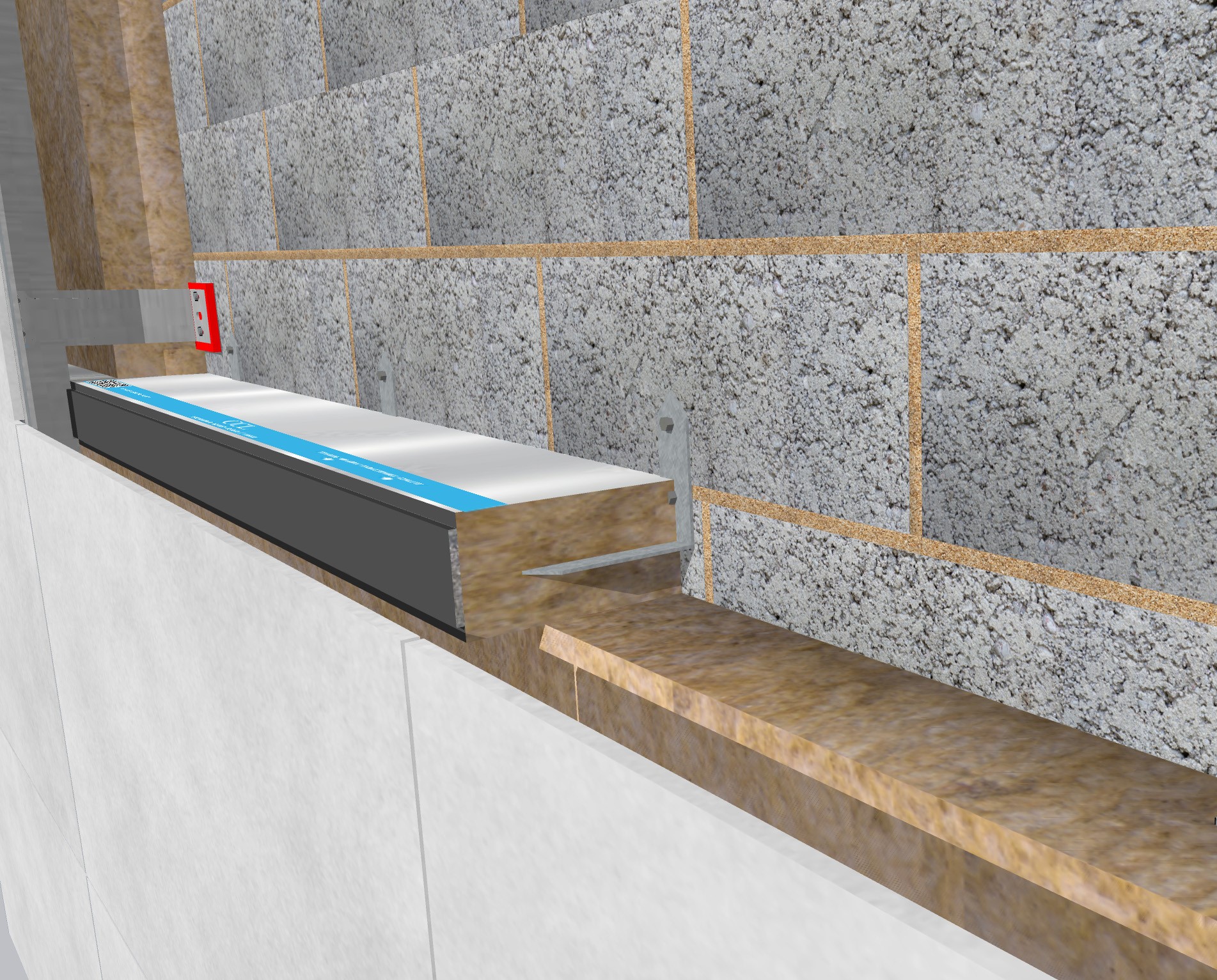

The CCL HRCB is a fire resistant barrier designed to prevent the spread of fire and smoke in open state cavities where a continuous vented air layer is required within the façade design.

Purpose

The CCL HRCB range is designed for use in ventilated façades, with cavities up to 300mm, where either 25mm or 50mm ventilated air layers are specified.

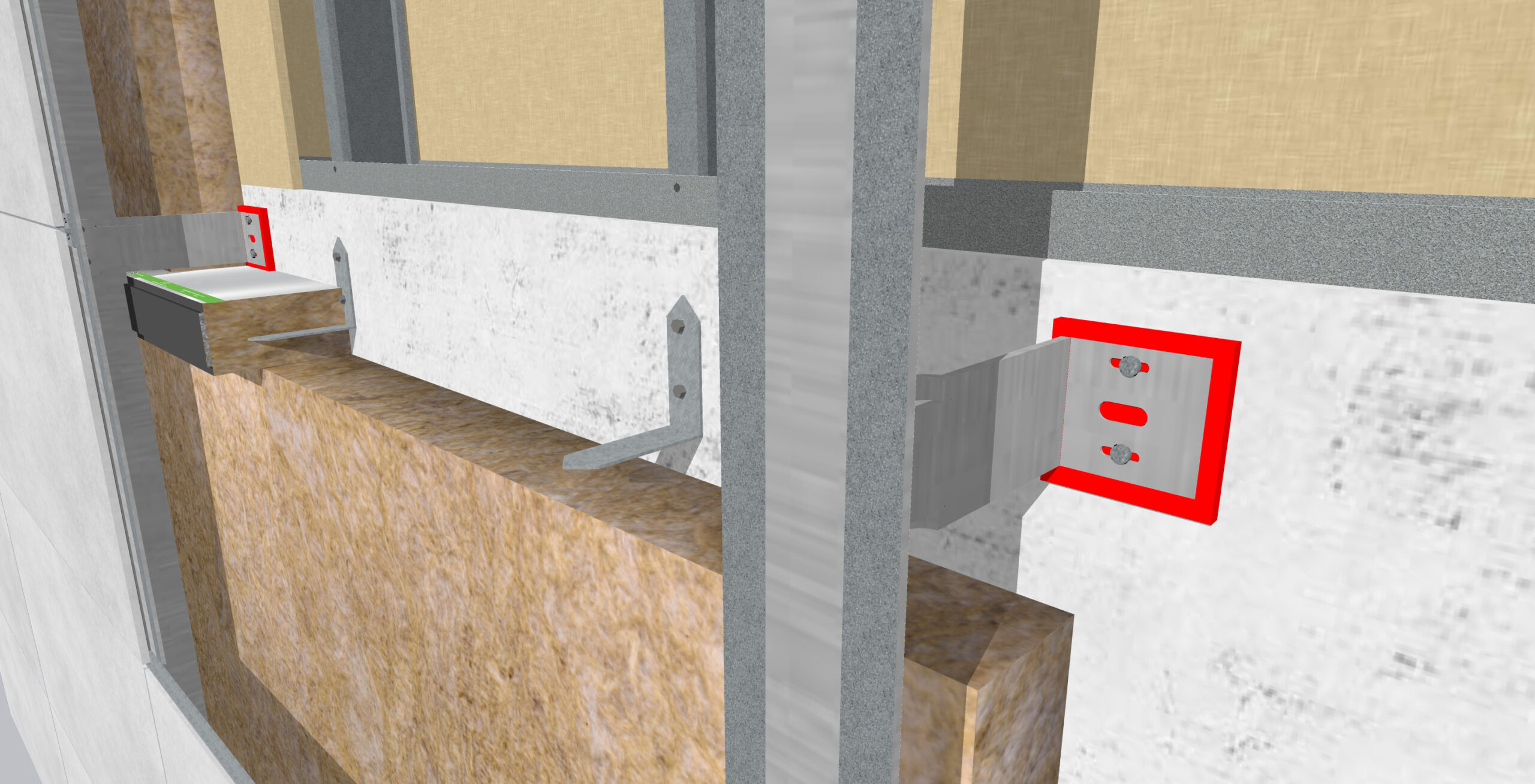

Manufactured using high density, non-combustible rock mineral wool combined with heat activated, high expansion intumescent, the barriers are mechanically fixed to the outer face of the inner substrate to prevent the spread of fire and smoke through the cavity zone.

Suitable for use on masonry and SFS wall types, the CCL HRCB range achieves fire ratings ranging from 60 to 180 minutes integrity and insulation*.

The CCL HRCB range are manufactured to suit the required cavity width, may also be trimmed on site when appropriate in order to meet building tolerances and may be paired with the CCL VRCB full fill barriers to complete the system.

Standards and Performance

The mineral wool core of a Concept Rainscreen Cladding Barrier achieves a fire classification of Euroclass A1 as defined in BS EN 13501-1.

The CCL HRCB range has been tested independently in accordance with the principles of BS EN1363-1 and ASFP TDG19.

Dimensions

The CCL HRCB is manufactured to suit specific cavity widths ranging between 75mm and 300mm including the vented air gap.

- HRCB Green 60/60 (E,I) 25mm air gap

- HRCB Orange 120/60 (E,I) 25mm air gap

- HRCB Black 180/90 (E,I) 25mm air gap

- HRCB Blue 60/60 (E,I) 50mm air gap

- HRCB Red 90/60 (E,I) 50mm air gap

Vertical Barriers

For vertical barriers in rainscreen systems it should be possible to fully fill the void with the CCL Vertical rainscreen cavity barrier (VRCB).

Installation

The CCL HRCB range should be mounted on brackets to the inner structural surface, using the CCL Multi bracket at a minimum of two per linear metre, or at a maximum of 500mm centres.

Further details can be found in our data sheet.